Product Description

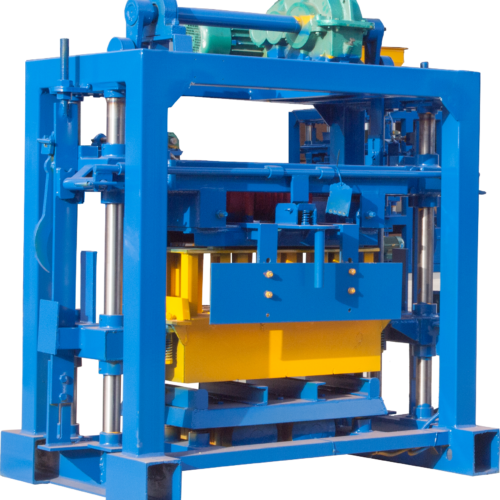

1.QT40-1 semi auto block making machine each part details

| No | ITEM | Function | Motor | Technical details |

| 1 | JD350 pan mixer | Used to mixer various raw materails like sand,fly ash cement,stone dust,aggregate. | 5.5KW | Diameter”1.2M |

| 2 | Belt Conveyor | Used to transport mixed material into block machine hopper | 1.1KW | Length:6000mm Width:400mm |

| 3 | QT40-1 block machine | Adopting electrical vibration to make various block brick by changing moulds | 13.45KW | No need installation ,can operate after connecting power |

| 4 | Block Trolley | Used to transport the blocks to stroage area | 0KW | 2sets |

| 5 | Pallet | Pallet is used to hold blocks,it can be recycled,usually 600pcs are enough | 0KW | 600pcs |

2.QT40-1block making machine technical parameter

| Overall size | 2060×1730×1850mm | Host machine power | 13.45KW |

| Molding period | 30S | Vibration force | 35.5KN |

| Pallet Size | 850×550×30mm | Pallet quantity | 600pcs |

| Weight | 3T | Mixer model | JD350 |

| Voltage | According to local condition | ||

Theoretical workshop area : 60m2 , need about 3-4workers .the office , curing area

and stacking area to arrange according your fact status.

3.QT40-1 Production Capacity

| QT40-1 Production capacity | |||

| Size(LxWxH) | Pcs/Mould | Pcs/ Hr | Pcs/ 8 Hr |

| 400X100X200 | 7 | 630-840 | 5040-6720 |

| 400X150X200 | 5 | 450-600 | 3600-4800 |

| 400X200X200 | 4 | 360-450 | 2880-3600 |

| 400X250X200 | 3 | 270-360 | 2160-2880 |

| 240x115x53 | 24 | 2160 | 17280 |

| 225X112.5X60 | 12 | 959 | 7679 |

| we can design molds according to your requests | |||

Capacity Mentioned is indicative only actual capacity varies with operator

efficiency and material quality etc